As the automotive industry leans towards a more evolved manufacturing system by producing autonomous vehicles, It’s supply chain transforms from something linear to more of a supply network based on real-time data sharing.

According to Sven Dharamani, Global Automotive Sector Supply Chain Leader at Ernst & Young, the failure to adopt more visible and agile processes is down to the longer model lifecycles that vehicle manufacturing is based on. Some of it is down to the combination of plant location and an ageing workforce.

Honda spends $1.2 billion in getting parts from its 600 tier one suppliers to its plants in the region and pointed out that cost pressures were increasing in the supply chain, with the shift towards electrification playing a major role.

George Grahovac, Senior Manager, Honda of America's

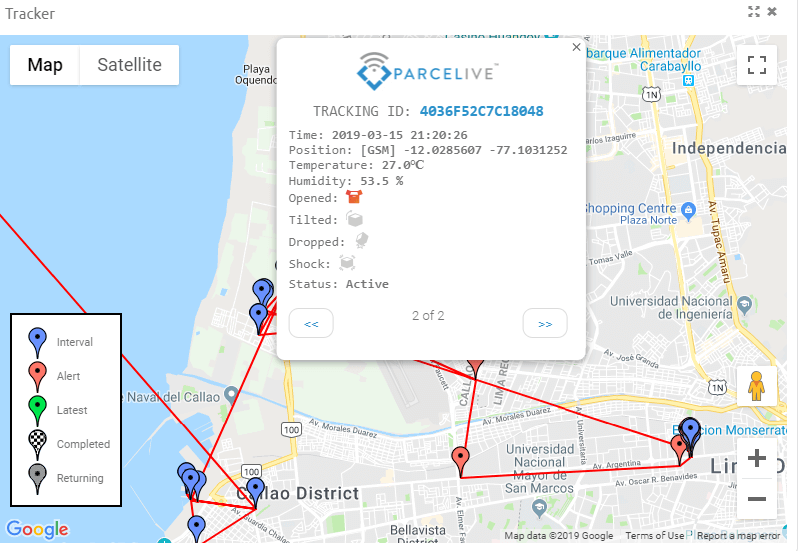

Unforeseen circumstances such as car accidents, traffic, customs checks and delayed flights can be dealt with by allowing ParceLive users to react and be pro-active about failures in real-time. With real-time alerts, ParceLive users in this instance will be able to access the security of their assets, such as the condition of lithium battery cells, ensuring that they have not been affected by intense fluctuating temperatures or impacts from poor handling.

Businesses need to capture the data as it happens and act upon it. Using ParceLive can help those in the automotive industry react in real time to incidents out of their hands whilst having invaluable visibility for the just in time production line.